CAMLINE Factory Dashboard

Real-time machine monitoring system for visualising and analysing production performance

Toward intelligent and efficient production

Camline FD (Factory Dashboard) is a modern software designed for monitoring and visualising production capacity, developed specifically to meet the needs of the machine shop industry. It provides a comprehensive and reliable solution for machine monitoring, enabling precise and real-time control of production processes.

Camline FD collects real-time data on the performance, status and operations of the production equipment and presents the data in a clear and visual format. Camline FD is a reliable tool for evaluating production performance, monitoring its efficiency and identifying potential problem areas.

1 Helps identify unused capacity and improve production process

2 Reveals problem areas in production and enables timely intervention

3 Facilitates production planning and resource optimisation

4 Serves as a useful tool in service and maintenance planning

5 Supports decision-making and strategic planning.

Table Of Content

Key features

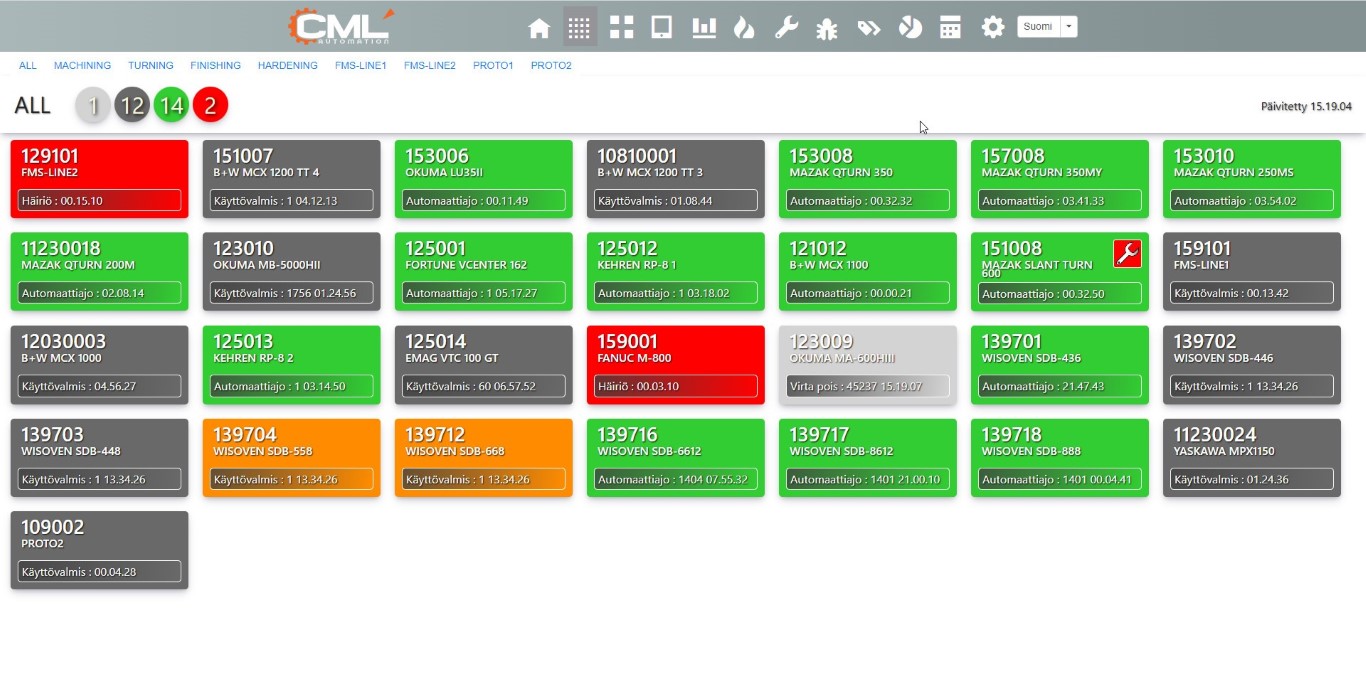

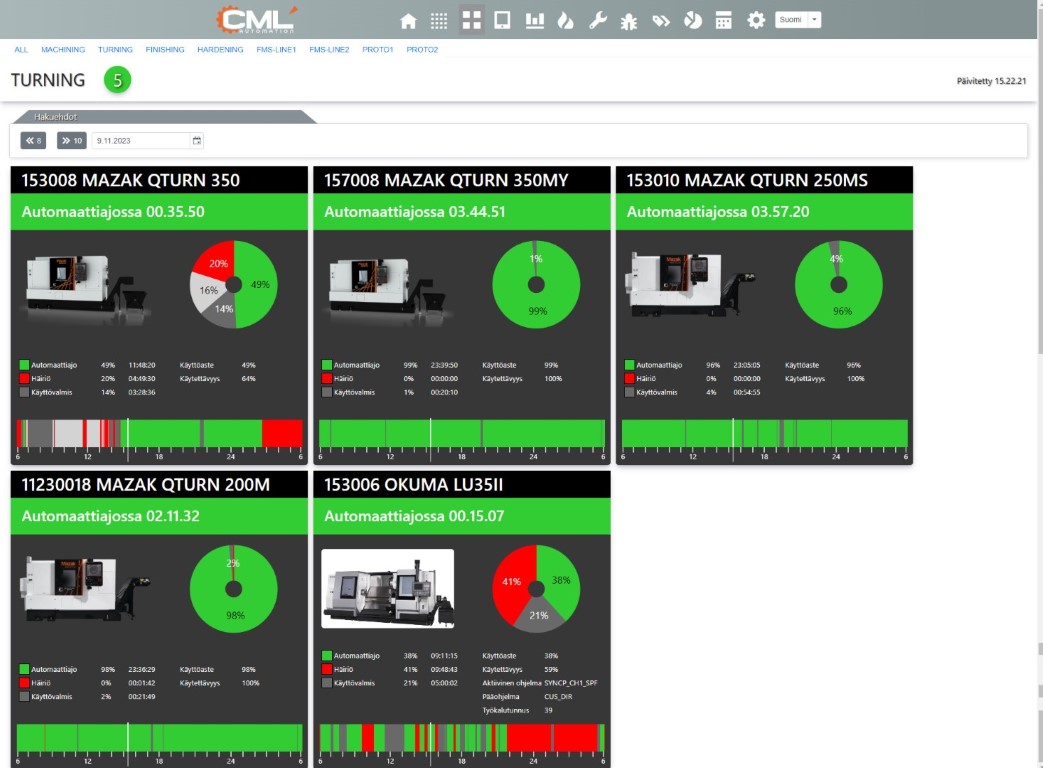

Different production views – Machine groups

It’s possible to create machine groups and monitor the group’s performance in a single view. The machine group view shows the real-time status of each machine in the group, status variations throughout the day, utilization and availability information plus active NC programs and tools.

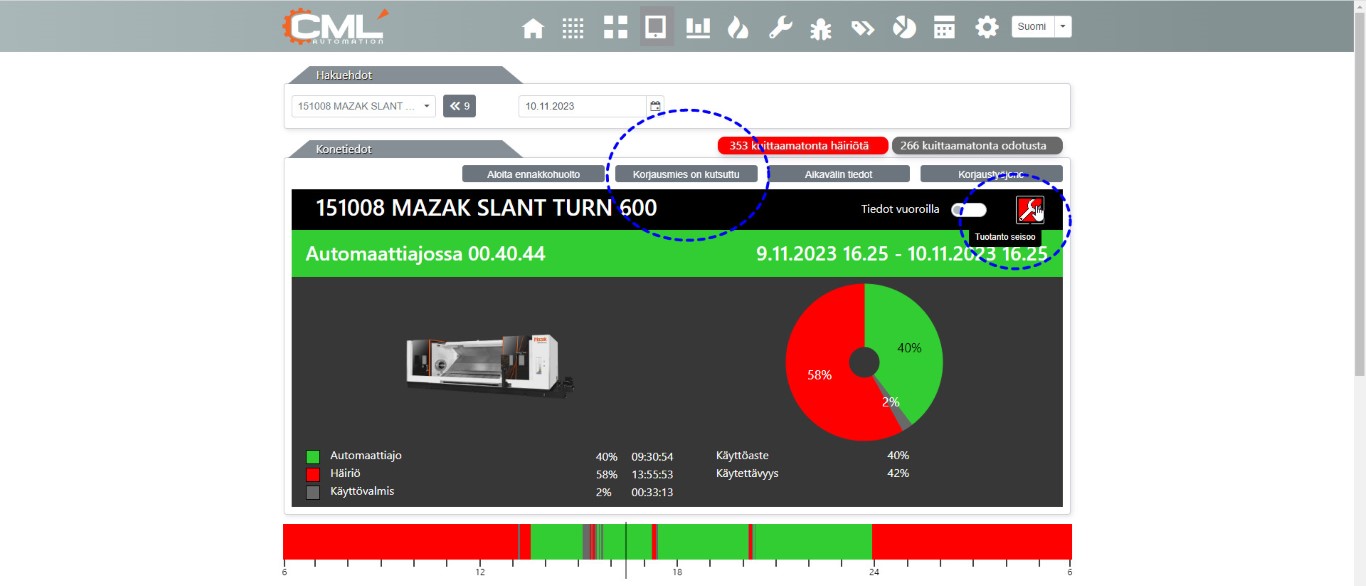

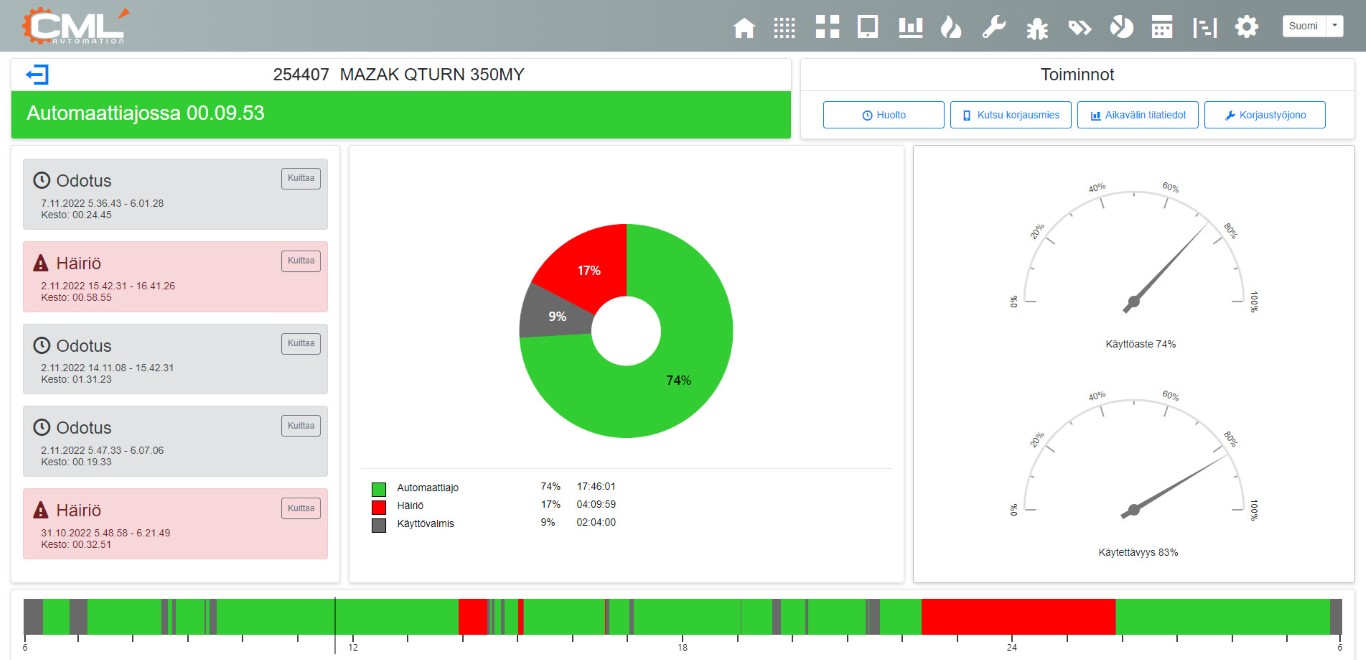

Different production views- Single machine view

Individual machine and its performance can be monitored in this view. The view shows more detailed information about the machine and in addition to the data displayed in the machine group view, the single machine view also shows information about the machining palette number and the number of completed pieces. In this view, it is also possible to set the machine to preventive maintenance mode and initiate a service call for the machine.

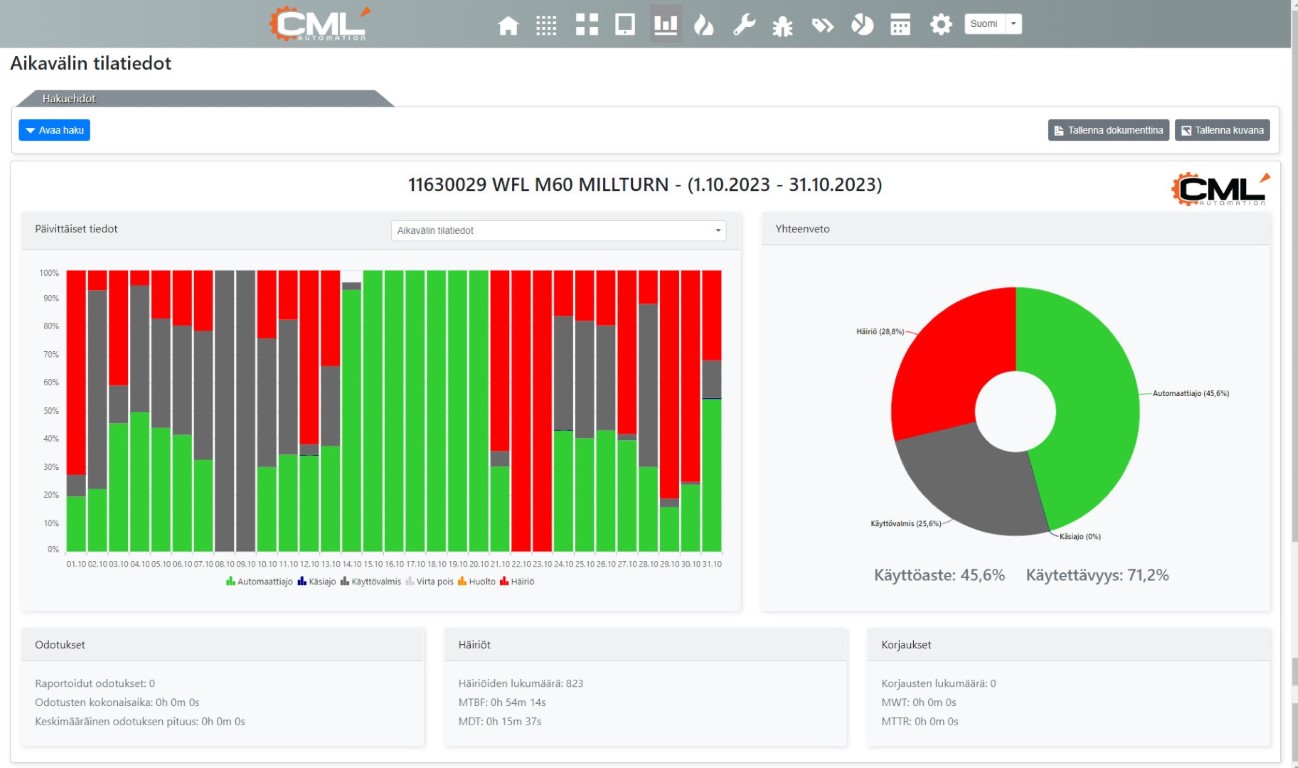

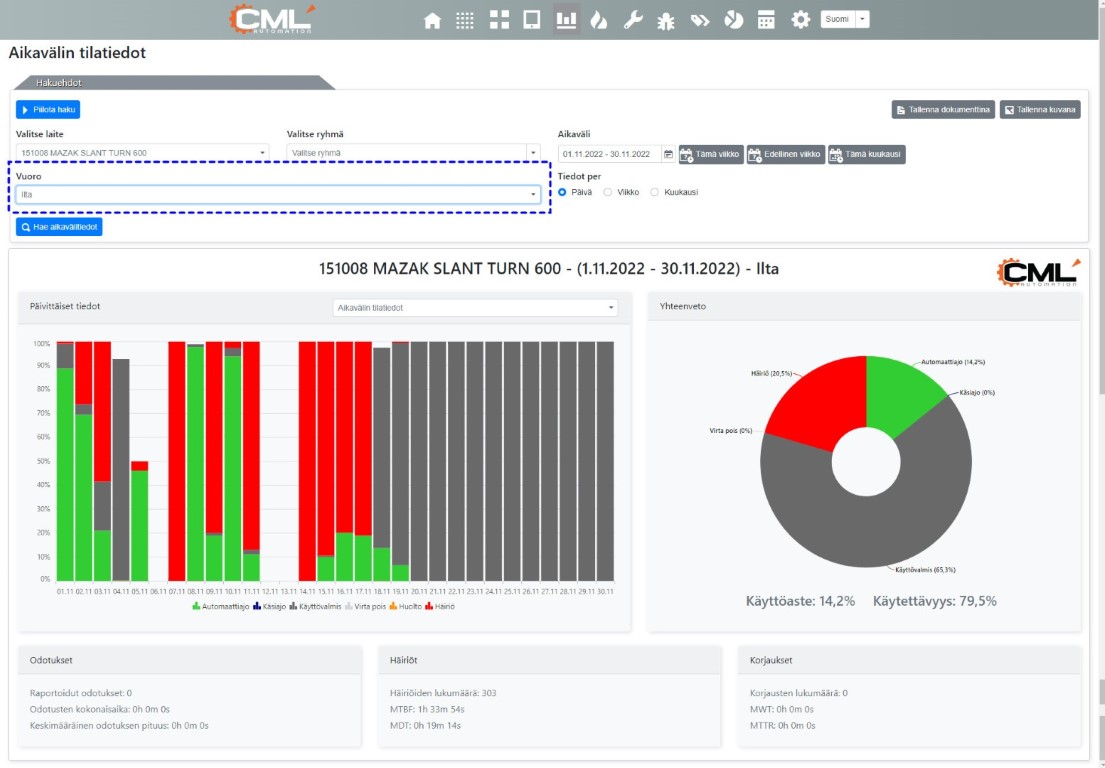

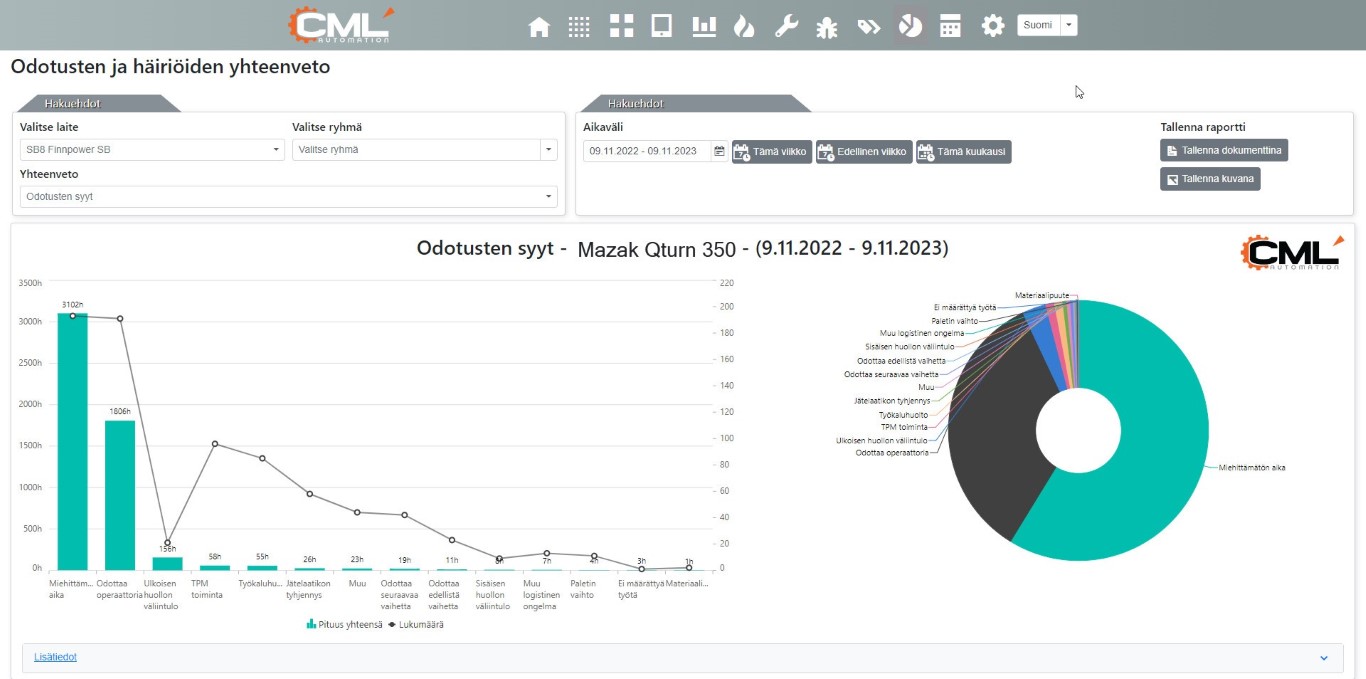

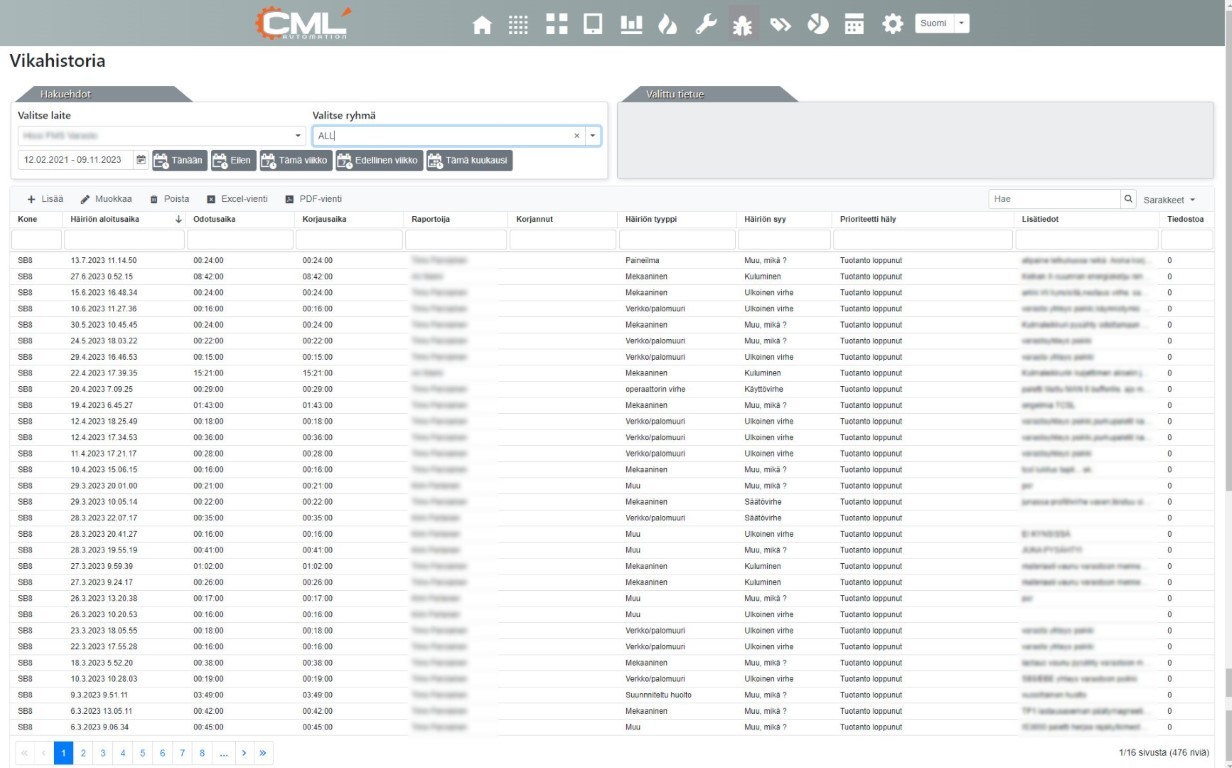

Downtime reporting

The system enables standardized reporting of waits and failures. Reported downtimes are saved in the fault and wait history for later analysis. Information about where failures and waits actually occur is valuable, e.g. in identifying equipment performance problems, planning maintenance and deciding on new investments.

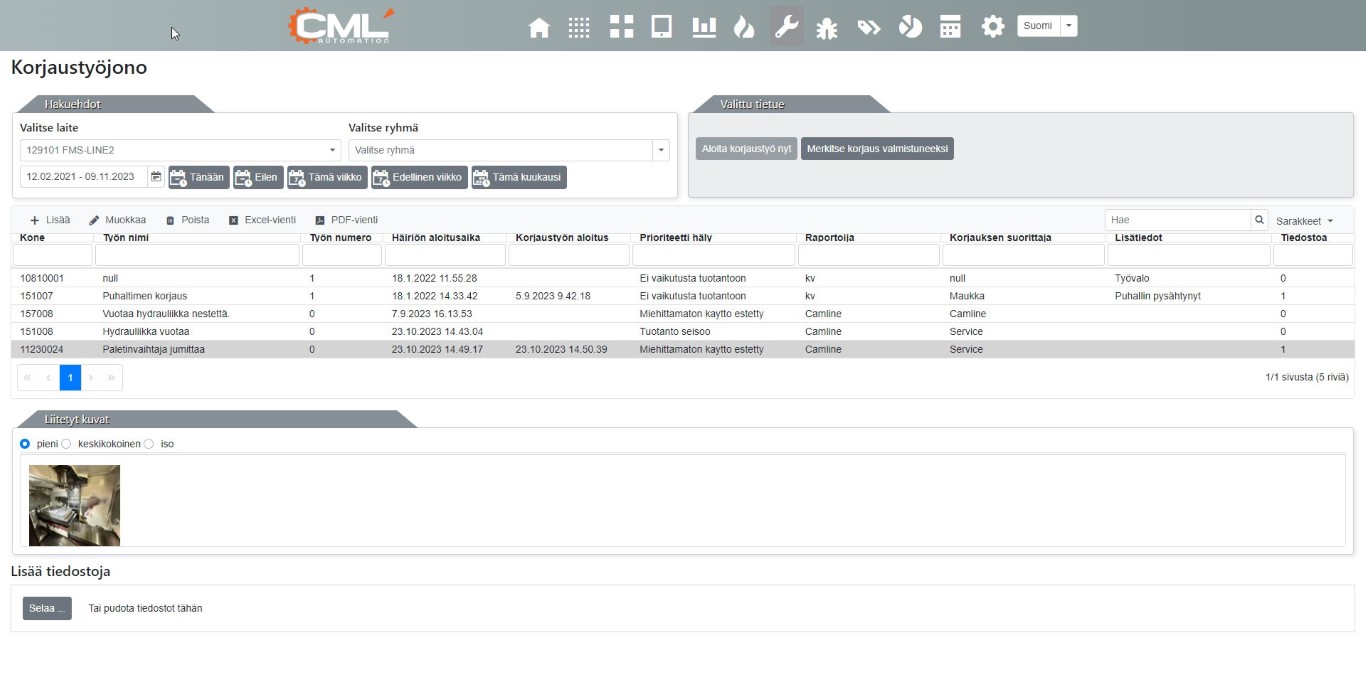

Repair job queue

For failures that require repair work, a repairman can be called directly from the user interface. Camline FD generates a queue for the upcoming service tasks and saves the performed repair and maintenance actions in the history database for later analysis. The stored information is useful for example in planning and monitoring maintenance activities.

Benefits

Visual and real-time overview of production

Camline FD is a visual tool that helps manage and improve production processes effortlessly and efficiently.

Five reasons why

Download the brochure

Download the brochure by filling in the form. We do not send marketing letters, and you will not be added to any mailing list. We will only contact you if requested.

Contact us

For more information about the Camline FD system, call +358 (0)291570 100 or send an inquiry using the form above.

INCREASED RELIABILITY WITH CAMLINE MODERNISATIONS!

Read more about our solutions for FMS and automated warehouse modernisations.